IoT Sensors in Construction: Real-Time Data That Actually Improves Profit Margins

Huzefa Motiwala September 24, 2025

IoT sensors are transforming construction by delivering real-time data that helps companies save money, improve efficiency, and boost safety. These sensors track equipment usage, monitor materials, and enhance worker safety, providing actionable insights that cut costs and keep projects on schedule. Here’s how IoT is making an impact:

- Equipment Monitoring: Track usage, reduce idle time, and prevent breakdowns with predictive maintenance.

- Material Management: Avoid waste, theft, and delays with smart inventory tracking and quality monitoring.

- Worker Safety: Use wearables to detect hazards, monitor locations, and improve site productivity.

- Data Analytics: Turn raw sensor data into insights for better decision-making, cost control, and improved timelines.

How Does IoT Enable Smart Construction Site Monitoring? – Civil Engineering Explained

Main Uses of IoT Sensors in Construction

IoT sensors are transforming how construction projects are managed, improving efficiency in areas like equipment tracking, material management, and worker safety. These advancements not only streamline operations but also contribute to better profitability.

Equipment Monitoring and Usage Tracking

Managing heavy machinery is one of the largest expenses on a construction site, making it an ideal starting point for IoT integration. By attaching sensors to equipment like excavators and bulldozers, companies can track real-time location, usage hours, and performance metrics across multiple sites.

For instance, IoT sensors can reduce fuel waste by identifying idle machinery, saving up to 2,000 liters of fuel per heavy machine annually [1].

A notable example comes from a French construction company that implemented IoT technology across 20,000 pieces of equipment at over 2,000 locations. Their system tracks asset location, utilization rates, and downtime percentages in real time. This data enables quicker problem-solving and reveals patterns that improve workflows [1].

Another key benefit is predictive maintenance, which prevents costly breakdowns. Sensors monitor metrics like temperature and vibration to detect issues early. One manufacturer saved approximately $700,000 annually across 500 machines by using predictive maintenance [1].

"IoT is making incredible headway in improving processes and systems in construction. The data suggests that IoT may fundamentally reshape how construction businesses operate, leaving traditional operations in the past." – Guest Writer, IoT For All [1]

Material Tracking and Quality Monitoring

IoT sensors also simplify material management and quality assurance, which are critical for staying within budget and on schedule. Real-time inventory tracking eliminates the inefficiencies and errors of manual monitoring.

A great example is concrete curing sensors, which measure temperature and moisture levels during curing. These sensors provide precise data on when concrete reaches the required strength, eliminating guesswork and unnecessary delays. This often shortens project timelines by several days.

Smart inventory sensors keep tabs on materials like rebar, lumber, and aggregates as they arrive and move through the site. They help prevent over-ordering, reduce theft, and ensure materials are available when needed. These sensors can also automate reordering when supplies fall below a set threshold.

Environmental sensors play a crucial role in protecting sensitive materials. For instance, temperature and humidity sensors monitor storage conditions for adhesives, sealants, and composites, helping to avoid material failures and rework due to improper storage.

Worker Safety and Productivity Tracking

IoT sensors aren’t just about equipment and materials – they also enhance worker safety and site productivity. Wearable devices, like smart hard hats and vests, track worker locations, detect falls, and monitor exposure to hazardous conditions. These devices alert supervisors in real time if workers enter restricted zones or if environmental conditions become unsafe, preventing accidents and minimizing delays.

Location tracking through wearables helps project managers optimize crew deployment and identify workflow bottlenecks. By analyzing activity data, managers can adjust staffing levels and improve efficiency. This data is also useful for accurate time tracking and billing across different projects or phases.

Environmental sensors placed around the site monitor air quality, temperature, and noise levels. When unsafe thresholds are reached, the system sends automatic alerts to supervisors and affected workers, reducing safety risks.

One construction company that adopted IoT asset tracking saw significant improvements after struggling with manual data collection. By connecting sensors to track equipment usage and environmental conditions, they scheduled maintenance earlier for machinery operating in harsh environments. This proactive approach extended equipment life and ensured peak performance [1].

These applications highlight how IoT sensors are driving smarter, data-driven decisions in construction, ultimately leading to better project outcomes and profitability.

Using Real-Time Data Analytics for Better Profits

Raw sensor data only becomes meaningful when it’s turned into actionable insights. IoT analytics platforms take the constant stream of information from construction sites and transform it into clear recommendations that help project managers save resources and speed up timelines. These platforms turn raw numbers into key performance metrics, giving teams the data they need to make smarter decisions.

In 2023, the software segment of IoT construction solutions accounted for over 49% of the market share[2], underscoring the growing importance of data analytics in the industry. These platforms go beyond simply collecting data – they identify patterns, predict potential challenges, and provide real-time guidance that directly impacts profitability.

Key Metrics Tracked by IoT Sensors

IoT analytics platforms monitor several performance indicators that help businesses make better financial decisions:

- Equipment utilization rates: These metrics show how often machines are in use versus sitting idle. With this data, companies can cut unnecessary rental costs and make better use of their assets.

- Material consumption tracking: By analyzing usage and waste patterns, project managers can identify areas where materials are overused. For instance, concrete sensors can compare the amount of material ordered to what’s actually used, flagging discrepancies that manual tracking might miss.

- Labor productivity metrics: These metrics measure worker activity and task completion rates, helping supervisors pinpoint bottlenecks and reassign crews as needed.

- Safety incident tracking: Wearable sensors monitor safety conditions, offering compliance documentation and insights into high-risk areas that need extra attention.

- Project progress indicators: By combining data from multiple sensors, these metrics provide real-time updates on the completion status of different project phases. This helps managers keep clients informed and identify potential delays early.

- Environmental monitoring: Data on weather, air quality, and other site conditions can be analyzed alongside productivity metrics to plan outdoor work more effectively and implement weather protection measures when needed.

By tracking these metrics, construction managers can connect sensor data directly to profit margins, uncovering opportunities to save money and improve efficiency.

Connecting IoT Data with Project Management Software

The true value of IoT analytics comes to life when sensor data integrates seamlessly with construction management software. This integration combines equipment status, material inventories, worker locations, and budgets into a single, easy-to-read dashboard.

- Real-time expense tracking: Budgets are updated instantly, helping project managers keep costs under control. This is why the project management segment led IoT applications in construction, capturing about 26% of the market share in 2023[2].

- Predictive analytics: By analyzing historical data, these tools can forecast delays and budget overruns. For example, if equipment sensors detect early signs of malfunction, the system can schedule maintenance during planned downtime, avoiding costly breakdowns.

- BIM integration: Real-time updates to 3D project models allow teams to compare actual progress against the plan, helping them catch design or construction issues early.

- Digital Twin technology: Virtual replicas of projects, updated with real-time sensor data, let teams test scenarios, optimize resources, and identify potential conflicts before they occur on-site.

- Automated reporting: By blending IoT metrics with budget, timeline, and milestone data, these systems generate reports automatically. This reduces the time spent on administrative tasks, giving managers more bandwidth to focus on critical KPIs and address problem areas.

Smart scheduling systems also play a role by adjusting work sequences based on real-time site conditions. Together, these tools empower project managers to make informed, profit-driven decisions and keep projects on track.

sbb-itb-51b9a02

Measurable Benefits of IoT in Construction

The impact of IoT in construction becomes even clearer when you look at the measurable benefits it brings. From cutting costs to improving safety, IoT technology plays a key role in boosting efficiency and profitability across the industry.

By using operational data, IoT sensors help minimize equipment downtime through predictive maintenance. This means less idle time, fewer breakdowns, and lower associated costs.

IoT-powered tracking systems also help reduce material expenses. They improve inventory management, cut down on waste, and even help prevent theft – saving money and resources.

When it comes to safety, IoT monitoring systems make a big difference. They reduce workplace accidents, which in turn lowers insurance costs and avoids delays caused by regulatory issues.

Another advantage is faster project completion. IoT enables better resource allocation and proactive problem-solving, helping teams stay on schedule, take on more projects, and keep overhead costs in check.

Compared to traditional methods, IoT delivers greater efficiency, better resource management, and improved budget control. It also enhances labor productivity by optimizing crew assignments and pinpointing workflow bottlenecks.

The data collected by IoT doesn’t just help in the moment – it’s also invaluable for future projects. It provides detailed insights into resource requirements and potential risks, making planning and bidding more accurate.

Finally, IoT energy monitoring tools help cut utility costs. Features like smart lighting, climate control, and scheduled equipment use not only save money but also support sustainability efforts.

How to Implement IoT Sensors in Construction

Starting with a clear strategy focused on quick wins is the best way to begin implementing IoT sensors in construction. By targeting areas where real-time data can deliver immediate benefits, you can build momentum and maximize the value these sensors bring to your projects.

Identifying the Right IoT Applications for Your Business

To make the most of IoT technology, focus on areas where your operations lack visibility. These blind spots often hold the greatest potential for improvement.

For example, you can monitor downtime for heavy machinery like excavators, cranes, and concrete mixers to cut idle time and boost efficiency. Smart inventory sensors can track materials such as lumber, steel, and concrete, alerting you to discrepancies early and helping avoid costly delays.

Worker safety is another critical application. Sensors that monitor employee locations and environmental conditions can reduce risks on-site, creating a safer workplace and helping you stay ahead of regulatory requirements.

The scale and duration of your projects also play a role in deciding how to implement IoT. Larger or long-term projects may justify a more comprehensive sensor network, while smaller jobs might benefit from a more targeted approach.

Integrating Systems and Meeting Compliance Standards

To fully benefit from IoT sensors, they need to integrate seamlessly with your existing systems, such as project management, accounting, and scheduling tools. This integration ensures that the data collected is actionable and contributes directly to improving efficiency.

For example, equipment sensors can automatically update maintenance schedules, inventory tracking can sync with accounting systems, and safety sensors can feed into HR and compliance reporting. These connections turn raw data into insights that drive smarter decisions.

Regulatory compliance is another key consideration. Worker monitoring tools must meet OSHA standards, and wireless devices should be FCC-certified. Additionally, ensure your data collection practices align with privacy laws and state-specific regulations. Consulting with legal experts can help clarify these requirements.

Finally, plan for the necessary network infrastructure. Construction sites often rely on cellular or satellite connections when Wi-Fi isn’t available, so allocate funds for data plans that can handle your sensor network’s bandwidth needs.

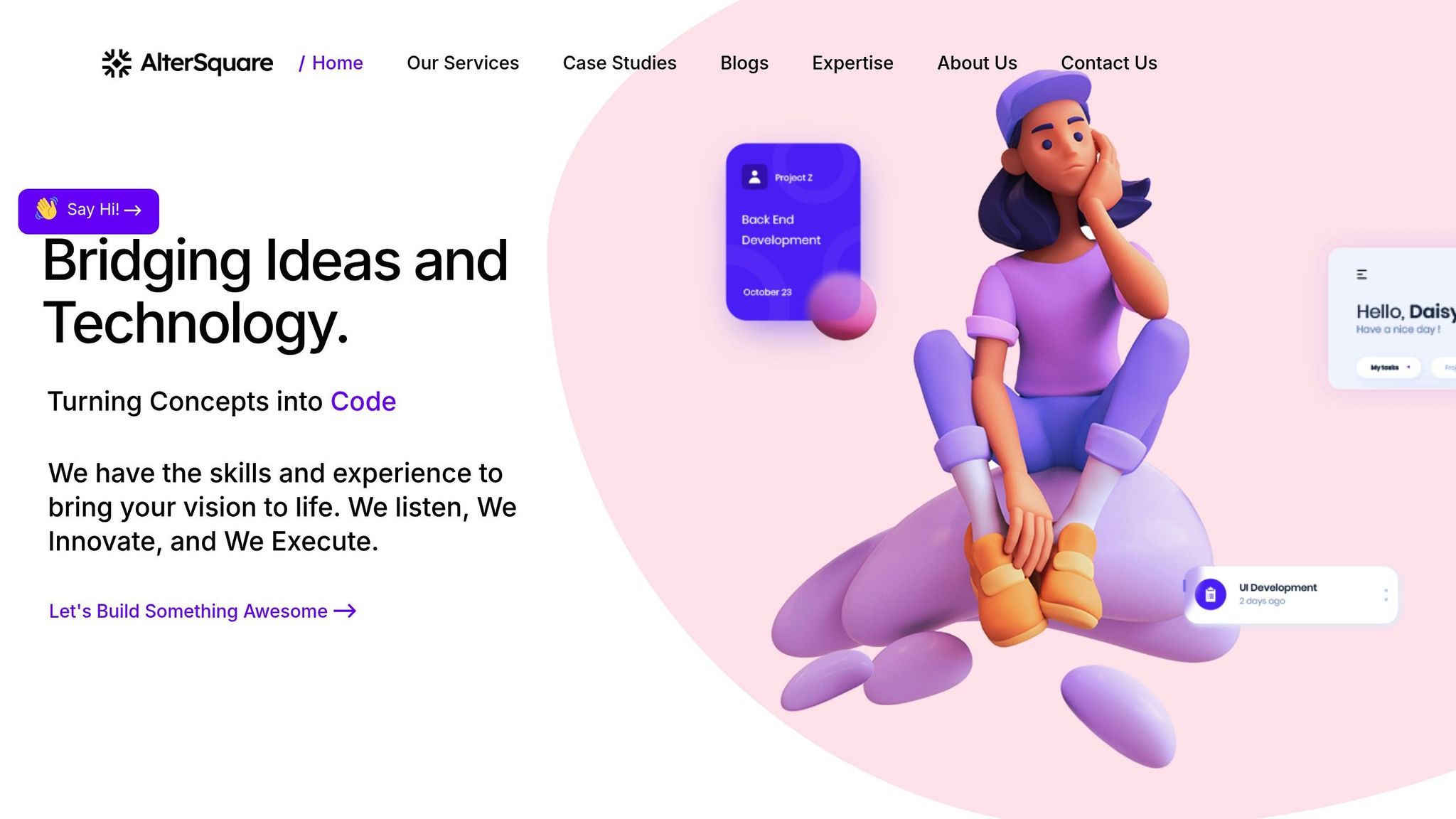

How AlterSquare Simplifies IoT Implementation

Developing custom IoT solutions can be a lengthy and expensive process, but AlterSquare offers a faster and more cost-effective alternative. Their rapid prototyping approach can get your system up and running in about 90 days, allowing you to start gathering valuable data and seeing results sooner.

Their MVP (Minimum Viable Product) development program focuses on high-impact use cases first, enabling you to achieve early wins while additional features are added over time. This phased approach helps you transition quickly from theoretical benefits to measurable outcomes.

AlterSquare also uses AI-powered analytics to turn sensor data into actionable insights, such as predicting maintenance needs and optimizing equipment usage. Their integrated product management ensures smooth system integration and scalability, while their tech team provides ongoing support to manage complex sensor networks. They also specialize in bridging new IoT systems with older software, ensuring compatibility and long-term performance.

To minimize risk, consider launching a pilot project. Focus on a single job site, a specific piece of equipment, or a particular material-tracking challenge. This smaller-scale implementation allows you to validate the return on investment before rolling out IoT solutions across your entire operation.

Conclusion: Growing Your Construction Business with IoT

IoT sensors are reshaping how construction companies approach profitability and efficiency. By converting hidden operations into actionable insights, they help drive better decision-making and boost overall performance.

The most effective IoT strategies focus on three key areas: monitoring equipment to cut downtime and maintenance expenses, tracking materials to avoid waste and delays, and implementing worker safety systems to reduce risks while enhancing productivity. This targeted approach translates into measurable cost savings and smoother operations.

IoT addresses common profit drains like idle machinery, misplaced materials, and safety incidents. With real-time monitoring, you can tackle these challenges head-on, responding to issues as they happen instead of uncovering them weeks later during project reviews. This proactive approach keeps projects on track and budgets under control.

Seamless integration with existing workflows is critical for achieving the best results. When IoT data is directly tied to daily operations, it leads to immediate, impactful improvements. Collaborating with an experienced team can accelerate this process. For example, AlterSquare’s 90-day MVP development program is tailored to the construction industry, delivering quick, tangible results by focusing on high-priority use cases first. This allows companies to see clear benefits while additional features are gradually rolled out.

As the construction industry continues its digital transformation, those who adopt IoT technologies are gaining a clear edge. By leveraging real-time data and analytics, these companies are achieving greater efficiency, lowering costs, and improving safety. The real question isn’t whether to adopt IoT – it’s how soon you can implement it to start reaping the rewards across your projects.

FAQs

How do IoT sensors help boost profit margins in construction projects?

IoT sensors are transforming the construction industry by offering real-time data that helps companies make smarter decisions and cut costs. Take equipment monitoring, for instance – these sensors can keep tabs on machinery around the clock, spotting potential issues before they escalate into costly breakdowns. This proactive approach slashes downtime and repair bills.

Beyond equipment, IoT sensors also keep an eye on resource usage, tracking things like fuel, materials, and energy. This data helps ensure resources are used efficiently, reducing waste and unnecessary expenses. With these insights, construction firms can fine-tune their operations, stick to project schedules, and trim costs – all of which contribute to stronger profit margins.

What are the biggest challenges when integrating IoT sensors into construction management systems?

Integrating IoT sensors into construction management systems isn’t without its hurdles. A major issue lies in device compatibility and limited interoperability – different technologies often struggle to communicate effectively, making smooth data exchange and integration a tough nut to crack.

Beyond that, there are other significant challenges to consider. Cybersecurity risks pose a constant threat, as connected devices can become vulnerable entry points for malicious attacks. Then there’s the matter of high upfront costs, which can be a deterrent for many organizations. And let’s not forget the specialized training required to ensure teams can actually make the most of these IoT tools.

Tackling these challenges calls for careful planning, standardization of technologies, and investing in workforce development. With the right approach, these barriers can be overcome, paving the way for a more efficient and connected construction process.

How can construction companies stay compliant with regulations when using IoT technology?

To ensure compliance when incorporating IoT technology, construction companies need to align with established standards for safety, security, and interoperability. It’s equally important to adhere to regional regulations, including FCC guidelines for devices that use radio transmitters.

On top of that, companies should establish clear internal policies, perform regular risk assessments, and keep detailed records of their compliance measures. Keeping an eye on regulatory updates is essential to stay aligned with changing industry requirements.

Leave a Reply