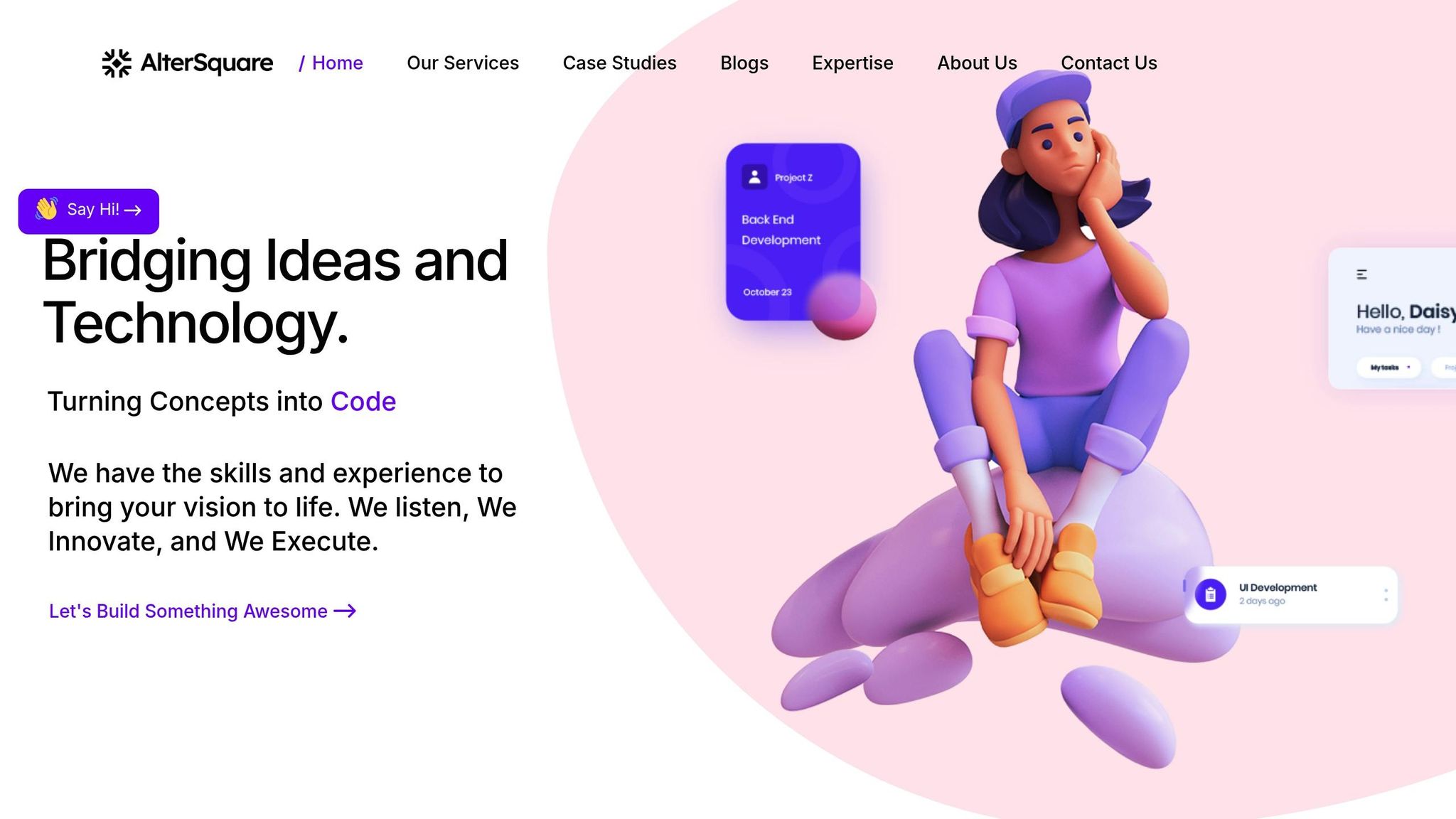

Digital twins are reshaping construction management by offering real-time insights into operations, improving safety, cutting costs, and reducing delays. These virtual replicas integrate data from IoT sensors, BIM models, and project management tools to provide actionable insights. Unlike traditional methods, digital twins enable proactive decision-making, helping companies achieve measurable ROI within 90 days.

Key Takeaways:

- What are digital twins? Virtual models of construction sites that update in real time using data from sensors, drones, and cameras.

- Why use them? They help reduce delays, improve safety, optimize resources, and enhance coordination.

- Quick ROI: Start with high-impact areas like equipment tracking, safety monitoring, or material management to see results in just three months.

- Implementation steps: Focus on planning, data integration, pilot testing, and continuous improvement.

- Tools and team: Use IoT sensors, cloud platforms, and analytics tools, supported by a skilled team including specialists in BIM, data, and project management.

By following a structured 90-day framework, construction companies can streamline processes, improve safety, and scale these benefits across multiple sites.

Digital twin of construction site

Getting Started: Finding Use Cases and Setting Up Data

To kick things off, focus on problems where digital twins can deliver quick, measurable results. Instead of trying to digitize everything at once, start small by targeting areas that can yield clear benefits within a 90-day window.

Finding High-Impact Use Cases

One great place to start is equipment tracking and maintenance. Downtime for heavy machinery can cost a fortune. By using IoT sensors to monitor engine hours, fuel usage, and performance metrics, digital twins can predict maintenance needs before a breakdown happens – saving both time and money.

Another key area is safety monitoring. Digital twins can track worker locations with wearable devices while also keeping tabs on environmental conditions like air quality, noise, and temperature. Pair this with geofencing technology, and you can automatically alert supervisors if workers enter hazardous areas or if conditions become unsafe.

Material management and supply chain optimization is another quick win. Digital twins can help track deliveries, monitor inventory, and predict shortages that might disrupt your project timeline. This added visibility helps keep materials flowing and minimizes delays caused by supply chain hiccups.

Lastly, progress tracking and quality control is a must. Using tools like drone surveys and 360-degree cameras to capture real-time site conditions, digital twins can compare actual progress against BIM models. This makes it easier to spot deviations early, preventing costly rework and keeping projects on track.

When choosing where to start, look for areas where you’re already collecting some data. Building on existing systems can make implementation faster and easier for your team. Once you’ve identified your focus, it’s time to organize your data to support these use cases.

Mapping and Organizing Data Sources

After you’ve zeroed in on your key use cases, it’s essential to organize your data sources for maximum impact.

- BIM models: These provide the foundation for construction digital twins, offering geometric and spatial context to visualize operations.

- IoT sensors and monitoring devices: These bring your digital twin to life with real-time data. Common examples include vibration sensors on equipment, air quality and temperature monitors, GPS trackers for vehicles, and load sensors on cranes. Place these sensors strategically on critical assets and high-risk areas.

- Project management systems: Tools like Procore, PlanGrid, or Microsoft Project supply scheduling, resource allocation, and progress updates. Integrating these platforms via APIs ensures your digital twin reflects the latest project data.

- Manual data inputs: For areas without sensors, rely on manual inputs like quality inspection reports, safety logs, and productivity metrics. Simple mobile interfaces can make this process easier for field teams.

- External data sources: Weather forecasts, traffic updates, and supplier schedules can provide extra context. For example, weather data can help adjust work schedules, while traffic insights might highlight potential delivery delays.

To keep everything running smoothly, create a unified data architecture that handles different data types, formats, and update frequencies. Assign clear ownership for each data source to ensure accuracy and timeliness.

Setting Up Data Standards and Quality Control

Reliable data is the backbone of a successful digital twin. Here’s how to maintain accuracy and meet your 90-day ROI goals:

- Data validation protocols: Use automated checks for sensor issues, manually verify critical measurements, and schedule regular calibration for equipment.

- Standardized naming conventions: Consistency is key. For example, use clear formats like "CRANE-01-TOWER-A" instead of mixing styles across teams.

- Data governance frameworks: Define who can access, edit, and approve data. Role-based permissions can give field supervisors access to operational data while limiting sensitive information to project managers. Regular audits can catch and fix inconsistencies before they cause problems.

- Quality control checkpoints: Build checkpoints into your data collection process. This could include sensor health checks, reviews for data completeness, and accuracy assessments.

- Data backup and security: Protect your investment by setting up automated backups, encrypting data, and restricting access with role-based permissions for subcontractors and external partners.

As your team becomes more comfortable with these systems, you can introduce more advanced validation rules. Starting with basic quality controls ensures that your digital twin delivers reliable insights, helping you achieve measurable improvements and stay on track for your 90-day goals.

Building Your Team and Choosing Tools

Once you’ve identified your data and established use cases, the next step is assembling a skilled team and equipping them with the right tools. Success hinges on a streamlined team supported by a tailored technology stack. Together, these elements pave the way for a smooth digital twin deployment and achieving ROI within 90 days.

Core Tools and Technologies

The technology stack is the foundation of any digital twin initiative. Start with tools for precise spatial data capture, such as 3D scanning technologies like LiDAR scanners, drones, and 360° cameras. Pair these with IoT sensors (e.g., temperature, humidity, GPS) to provide real-time data streams into cloud-based platforms.

Cloud platforms are essential for managing and analyzing incoming data efficiently. Scalable digital twin platforms enable seamless integration, efficient data handling, and real-time processing.

For connecting existing models to live data, BIM integration software is indispensable. It syncs with project management tools, ensuring accurate data visualization and analysis.

Finally, analytics and visualization tools transform raw data into actionable insights. Platforms like Power BI or Tableau allow teams to build custom dashboards, making it easier to identify trends and make informed decisions quickly.

Team Roles and Responsibilities

A successful digital twin team brings together experts from various fields, each playing a critical role in the project’s success:

- Digital Twin Specialist: Oversees model creation, data integration, and system maintenance, combining expertise in BIM, analytics, and IoT [1].

- Project Managers: Define use cases, set ROI targets, and manage resource allocation efficiently [2].

- BIM Specialists: Develop and update digital models while collaborating with architects and engineers to ensure precision [1].

- Data Analysts: Analyze sensor data and project metrics, turning them into meaningful insights through dashboards and actionable recommendations.

- Field Leads and Site Supervisors: Act as the bridge between digital systems and on-site operations, ensuring accurate data collection and training teams on digital tools [3].

- Safety and Maintenance Teams: Use digital twins to assess risks, simulate maintenance scenarios, and optimize resource use [2].

Collaboration is key. Real-time shared models allow all stakeholders to stay informed and work together to address challenges effectively. For instance, a KPMG report highlights that 45% of construction companies already use digital analytics tools, and 68% plan to adopt advanced systems soon [3].

"Digital twin technology is not a fancy tool for the chosen ones. In my professional judgment, it’s a strategic imperative for the construction industry. In the industry where precision, efficiency, and safety are paramount, digital twins stand as the backbone of modern construction project success. This technology is all about enhancing the way you plan projects, optimize processes, ensure a secure working environment, and more. No doubt digital twins are the practical solution that keeps our construction projects running smoother and smarter." – Alina Filatova, Head of BA Department at Innowise [3]

Using AlterSquare‘s Structured Delivery Framework

AlterSquare’s Framework offers a structured approach to accelerate deployment and ROI. Designed for startups and growing companies, it ensures a reliable rollout that delivers results within 90 days.

- Discovery Phase: Identify high-impact use cases and map data sources. ROI targets are defined within one to two weeks.

- Design and Validation Phase: Develop the technical architecture and verify data flows before full-scale implementation. AlterSquare ensures seamless integration with existing systems, including project management tools, BIM software, and IoT devices. Key dashboards are prototyped, and data quality is tested.

- Agile Development: Projects are broken into short sprints, enabling rapid iteration and continuous improvement. Each sprint delivers functional components for testing and feedback, ensuring the final system aligns with real-world needs.

- Launch Preparation: Comprehensive training programs focus on practical skills and hands-on experience [3]. AlterSquare also provides a shared platform that fosters collaboration, allowing stakeholders to exchange information and coordinate effectively.

Post-launch, AlterSquare continues to monitor performance, offer ongoing training, and scale the system to additional projects. This ensures long-term ROI well beyond the initial 90-day target.

sbb-itb-51b9a02

90-Day Digital Twin Implementation Plan

Building on the steps outlined earlier, here’s a phased approach to rolling out a digital twin within 90 days. By breaking the process into four clear stages, you can track progress, maintain focus, and work toward measurable ROI. Each phase builds on the last, creating momentum while leaving room for adjustments along the way.

Phase 1: Planning and Strategy

Days 1-15: Laying the Groundwork

Start by setting clear, measurable goals tied to your business objectives. For example, you might aim to reduce delays, lower material costs, or improve safety measures. Establish baseline metrics from your current operations so you can track progress effectively.

Choose a pilot project that’s both visible and manageable. A mid-sized construction site often works best – it’s complex enough to showcase the benefits of a digital twin but not so large that it becomes overwhelming. Focus on a site where existing challenges can be addressed with this technology.

Document your current workflows, data sources, and access requirements to avoid unnecessary scope expansion. This ensures the digital twin addresses real, actionable needs rather than hypothetical scenarios.

Lastly, create a detailed project charter that outlines roles, responsibilities, timelines, and budgets. Include contingency plans for common issues like delays in data integration or hardware procurement. With this foundation in place, you’ll be ready to move into the next phase: integrating your data.

Phase 2: Data Integration

Days 16-45: Building a Solid Data Framework

Using the standards defined in the planning phase, start integrating your key data sources into one unified system. Prioritize critical data streams like BIM models, IoT sensor data, and project management tools.

Adopt a cloud-based solution to efficiently process large volumes of daily sensor data and 3D scans. Connect your existing software systems using APIs and data connectors. The goal is to complement your current workflows, not replace them, so ensure the digital twin integrates seamlessly with tools already in use for scheduling, financial tracking, and project management.

Apply data governance protocols to maintain accuracy and security. Before moving forward, test your data flows by running sample data through the system. This helps identify and resolve any integration issues early on.

Phase 3: Model Development and Pilot Launch

Days 46-75: Deploying the System

Enhance your BIM models by importing existing designs and layering in real-time data. Focus on critical areas like structural components, equipment placement, and high-risk zones. Deploy IoT sensors strategically to monitor key conditions such as temperature and equipment locations.

Set up real-time data feeds to keep your digital twin updated continuously. Configure automated alerts for critical thresholds, ensuring immediate attention to potential issues. Launch the pilot system with a small group of users – typically site supervisors, project managers, and safety coordinators – and train them on the tools. Encourage feedback from these users through simple reporting channels to identify any issues or improvement areas.

Phase 4: Testing and Improvement

Days 76-90: Fine-Tuning and Validating

Run comprehensive system tests under real-world conditions. Simulate scenarios like equipment failures, weather disruptions, or safety incidents to ensure the system responds as expected. Validate that alerts function properly and that data meets the quality standards you’ve set.

Gather feedback from stakeholders and compare the results to your initial metrics. Document achievements like cost savings, time efficiencies, and risk reductions. Use this information to refine workflows based on real-world usage and update your standard operating procedures.

These final adjustments prepare your team to scale the digital twin solution across additional sites. Document lessons learned, update training materials, and identify new projects or use cases for expansion. Create a playbook to guide future implementations, ensuring consistent results and long-term success.

Measuring ROI: Tracking Results and Scaling Up

After completing your 90-day deployment, the next step is to measure the impact and plan for scaling your success. By quantifying the benefits and strategically expanding your digital twin solution, you can maximize its value across multiple projects. To do this effectively, focus on tracking the right metrics, using data-driven insights, and creating a clear roadmap for growth.

Key Metrics for ROI

Start by identifying the metrics that matter most for measuring ROI:

- Cost Reduction Metrics: Compare material waste percentages before and after implementation. Track how digital twins help reduce rework costs by catching design conflicts or issues early.

- Time and Efficiency Gains: Measure how well your project adheres to the schedule by comparing planned vs. actual milestone dates. Also, monitor equipment utilization rates to see how often machinery is operating at optimal capacity rather than sitting idle.

- Safety and Compliance Improvements: Track safety violations and compliance audit scores to quantify how digital twins enhance regulatory adherence and reduce risks.

- Operational Cost Savings: Use IoT sensors to monitor energy consumption and labor productivity, identifying areas where workflows have become more efficient.

To calculate ROI, total these savings and compare them to the costs of implementing the digital twin. Many companies find that they break even quickly, with ongoing savings delivering positive returns over time. These metrics provide the foundation for real-time analysis and smarter decision-making.

Real-Time Results Analysis

Real-time analysis ensures you’re not just collecting data but turning it into actionable insights:

- AI-Driven Analytics: Use real-time dashboards to highlight key performance indicators (KPIs) and take immediate action. Predictive analytics can also help forecast delays, cost overruns, or safety risks based on historical and current data.

- Automated Reporting Systems: Simplify the measurement process by generating automated reports with visual dashboards. These reports should spotlight both successes and areas that need improvement.

- Decision-Making Dashboards: Provide stakeholders with high-level overviews of key metrics like cost savings, schedule improvements, and safety enhancements. Automated updates ensure the data remains accurate and up-to-date.

- Performance Benchmarking: Compare your results to industry standards to validate your ROI and identify areas for further improvement.

Document lessons learned throughout this process. Identify the most valuable metrics, effective data sources, and successful analytical methods. This documentation will be crucial as you scale to additional sites.

Expanding Digital Twin Solutions

Scaling up your digital twin solution requires a thoughtful approach:

- Site Selection Strategy: Focus on high-impact sites that share similarities with your pilot project. Look for locations where baseline metrics suggest strong potential for improvement.

- Standardization and Replication: Use insights from your pilot to create standardized protocols for data collection, sensor placement, and integration. Develop training materials and checklists to streamline future deployments.

- Technology Stack Scaling: Ensure your cloud infrastructure and analytics platforms can handle increased data volumes as you expand. Upgrade systems as needed to maintain performance.

- Team Development and Training: Identify team members who excelled during the pilot and position them as champions for future projects. Create training programs to quickly onboard new team members.

- Budget Planning for Expansion: Factor in costs for sensors, software licenses, and implementation time. As you scale, per-site costs often decrease, and faster timelines for new deployments can further improve efficiency.

- Integration with Enterprise Systems: Connect digital twin data with tools like ERP systems and corporate dashboards to provide organization-wide visibility and support better decision-making.

- Continuous Improvement Frameworks: Regularly review performance, update procedures, and adopt new technologies. Sharing feedback between sites allows improvements in one location to benefit the entire network.

Consider starting with a phased expansion rather than rolling out the solution everywhere at once. This approach lets you refine processes, address challenges, and build expertise gradually. Each successful deployment strengthens your organization’s confidence in the technology.

As your digital twin network grows, explore advanced capabilities such as cross-site analytics, predictive modeling, and integration with emerging technologies like artificial intelligence. These features can unlock even more ROI opportunities and help you maintain a competitive edge in the construction industry.

Conclusion: Building Long-Term Value with Digital Twins

Digital twin technology is reshaping the construction industry, giving companies the tools to operate more efficiently, stay competitive, and grow in a sustainable way. The 90-day implementation framework outlined here provides a practical roadmap for achieving measurable results while setting the stage for long-term success.

A Quick Look at the 90-Day Implementation Framework

This framework emphasizes starting with impactful use cases that demonstrate value quickly, rather than aiming for perfection right away.

The process is broken into four phases – planning, data integration, pilot launch, and testing – to minimize risks and deliver results faster. By following this structured approach, companies can gain actionable insights early on, refine their processes for future rollouts, and build a foundation for long-term improvements. This method not only boosts efficiency and safety from the start but also helps teams develop the expertise needed to scale these benefits across multiple projects.

Treating the initial deployment as a learning opportunity is crucial. Each phase builds on the last, creating a ripple effect where future deployments are faster, smarter, and more impactful.

Leveraging AI and Continuous Improvement for Growth

Once the initial framework delivers its first successes, incorporating AI and continuous improvement processes can amplify those gains. AI-powered analytics transform raw sensor data into predictive insights, allowing project managers to foresee and address challenges before they become major issues.

For example, machine learning can analyze a wide range of data – such as weather patterns, equipment performance, labor productivity, and material deliveries – to uncover hidden opportunities for optimization. This proactive approach shifts the focus from reacting to problems to preventing them entirely.

A continuous improvement cycle ensures the digital twin system evolves alongside project demands. Regular reviews, feedback loops, and updates keep the system aligned with business goals. As digital twins are deployed across multiple sites, cross-project analytics can uncover broader trends, helping teams standardize best practices and drive innovation even further.

Why AlterSquare?

AlterSquare is uniquely positioned to help companies accelerate their digital twin journey. Specializing in engineering-as-a-service, AlterSquare works with startups and growing construction firms to implement tailored digital twin solutions. Acting as an extension of your team, they bring the technical expertise needed to create solutions that deliver results.

Their structured delivery model aligns seamlessly with the 90-day implementation framework, emphasizing clear roadmaps, user-focused design, and rapid iteration. For businesses looking to modernize their operations, AlterSquare provides the know-how to navigate the complexities of digital twin technology. With a focus on delivering immediate results and building long-term value, AlterSquare ensures your investment in digital twins translates into real-world advantages and a stronger competitive edge.

FAQs

How do digital twins enhance safety and efficiency on construction sites in just 90 days?

Digital twins enhance safety and streamline operations on construction sites by offering real-time insights into daily activities. This technology enables managers to spot and resolve potential safety risks promptly, helping to reduce accidents. With improved visibility, teams can refine workflows, minimize mistakes, and eliminate unnecessary delays, paving the way for quicker and more efficient project completion.

On top of that, digital twins utilize predictive analytics to foresee and address issues before they become problems. By adopting these tools, construction companies can improve coordination, make better use of resources, and see tangible results – often within just 90 days of putting them into action.

What tools and technologies are essential for creating a digital twin in construction projects?

To bring a digital twin to life for a construction project, you’ll need the right mix of cutting-edge tools and technologies. Start with 3D modeling software like Revit or Navisworks to build detailed virtual replicas of physical structures. Then, incorporate IoT sensors to gather real-time data directly from the construction site. This data becomes even more powerful when paired with AI-driven analytics, which can help anticipate maintenance needs and guide smarter decisions.

You’ll also want to include GIS technology for mapping and spatial analysis, along with tools that seamlessly integrate field data into the digital twin. When combined, these technologies create a dynamic, data-rich system that makes managing construction projects more efficient, cost-effective, and less risky.

What are the best ways for construction companies to measure the ROI of digital twin technology, and which metrics should they prioritize?

Construction companies can evaluate the return on investment (ROI) of digital twin technology by focusing on specific metrics that directly influence costs, efficiency, and safety. Here are some key areas to monitor:

- Cost savings: Look at reductions in rework, material waste, and delays that can inflate project budgets.

- Efficiency improvements: Consider how digital twins speed up project timelines, optimize resource use, and enhance clash detection during planning.

- Risk mitigation: Track decreases in safety incidents and improvements in quality control processes.

By keeping an eye on these factors, companies can clearly see the financial and operational benefits of adopting digital twin technology. Many firms have reported recovering their initial investment within a few months, thanks to noticeable gains in project performance.

Related Blog Posts

- Mobile-First Construction: Bringing Field Operations into the Digital Age

- Beyond BIM: How Digital Twins are Revolutionizing Construction Project Management

- IoT Meets BIM: Practical First Steps to a Maintainable Digital-Twin Stack

- IoT Sensors in Construction: Real-Time Data That Actually Improves Profit Margins

Leave a Reply