Computer Vision vs Human Inspectors: Construction Quality Control Showdown

Huzefa Motiwala September 20, 2025

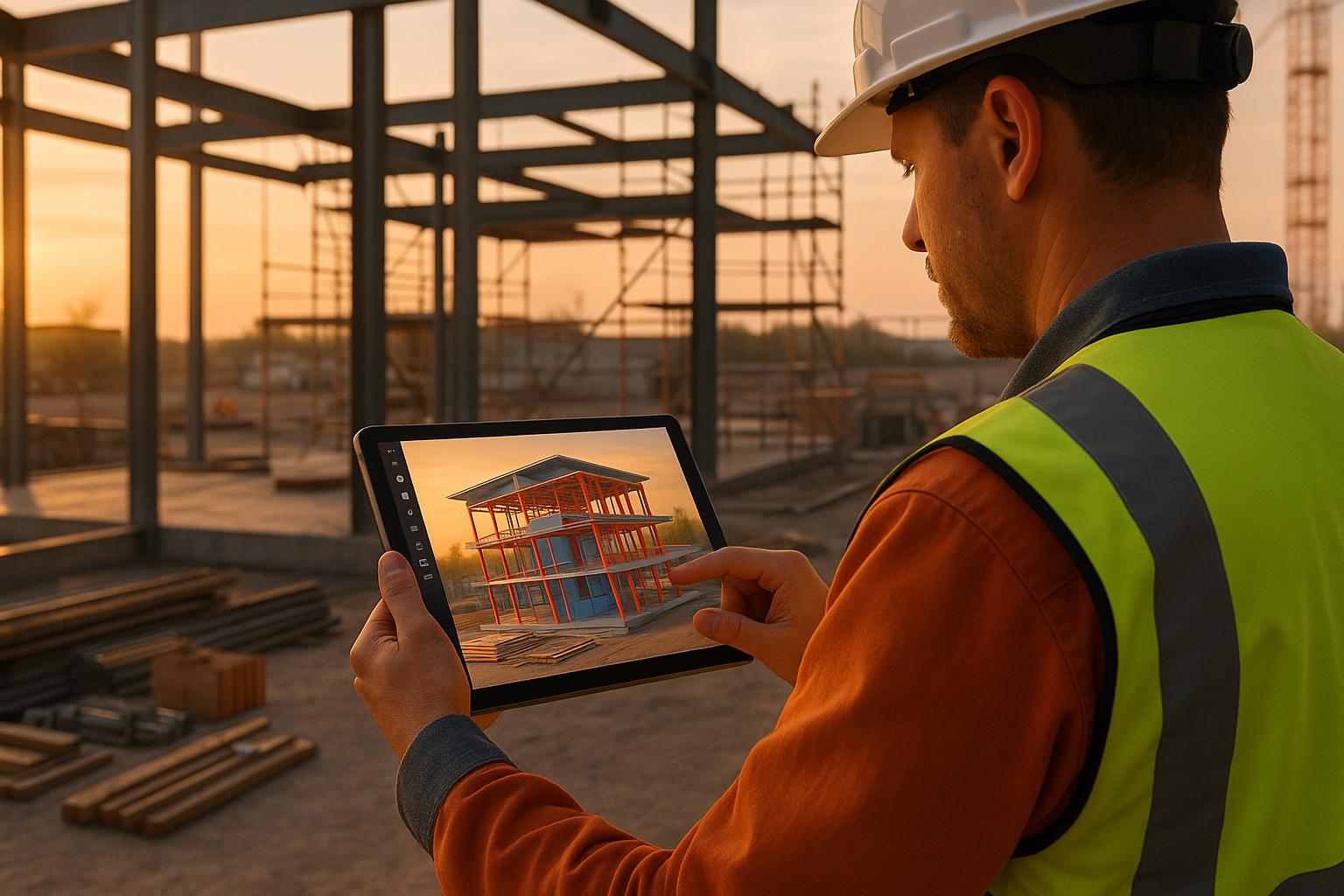

Construction quality control is critical for safety, durability, and cost management. The debate between computer vision and human inspectors highlights their unique strengths and limitations. Here’s the core takeaway:

- Computer vision: AI-powered cameras and sensors provide 24/7 monitoring, detect defects with 98–99.5% accuracy, and streamline progress tracking with automated reporting. Ideal for repetitive tasks like identifying cracks or misalignments.

- Human inspectors: Bring nuanced judgment, regulatory expertise, and adaptability to complex scenarios. Essential for site-specific evaluations and ensuring compliance with safety and building codes.

The best approach combines both methods: Computer vision handles routine inspections, while human inspectors focus on intricate decisions and compliance. Startups can save time, reduce errors, and improve outcomes by leveraging this hybrid strategy.

Quick Comparison

| Factor | Computer Vision | Human Inspectors |

|---|---|---|

| Accuracy | 98–99.5% for specific defects | 70–85% (may miss 20–30% of issues) |

| Speed | Continuous, real-time monitoring | Limited by manual coverage |

| Strengths | Consistency, automation, scalability | Judgment, context, regulatory insight |

| Weaknesses | Requires setup, high upfront cost | Fatigue, scalability challenges |

For startups, balancing both methods ensures efficient and high-quality construction project management.

How Construction Managers Can Use AI For Site Monitoring

Computer Vision in Construction Quality Control

Computer vision is changing the game for construction quality control by using AI-powered cameras and sensors to monitor sites in real time. Instead of relying on periodic human inspections, this technology offers constant oversight, identifying defects and tracking progress the moment issues arise. Here’s a closer look at how it’s reshaping quality control on construction sites.

How Computer Vision Works in Construction

Computer vision systems act as automated inspection tools, continuously analyzing construction sites through cameras and AI algorithms. They excel at spotting structural defects, safety violations, and other issues that might go unnoticed during traditional inspections.

Defect detection is a standout feature. These systems can identify cracks, misalignments, and material inconsistencies as they emerge. Unlike human inspectors, who might visit a site once or twice a day, computer vision provides uninterrupted monitoring, catching problems early – before they escalate into costly repairs.

Progress tracking is another major advantage. These systems automatically monitor daily work, compare it against project schedules, and update management systems in real time. This eliminates the need for manual progress reports, giving stakeholders accurate, up-to-date insights without added effort.

Additionally, computer vision enhances safety by detecting improper use of personal protective equipment (PPE) and identifying unsafe conditions. Supervisors are alerted immediately when safety protocols are breached, helping to prevent accidents before they occur.

Key Features of Computer Vision Systems

Modern computer vision systems come equipped with advanced features that make them indispensable for quality control on construction sites:

- High-resolution image analysis: These systems can detect even the smallest defects, like hairline cracks in concrete or slight misalignments in structures – issues that might escape the human eye.

- Automated reporting: Forget the paperwork. These systems generate detailed reports that include photos, measurements, and analysis, streamlining documentation and meeting regulatory standards without manual input.

- Seamless integration: They connect directly with construction management software, BIM platforms, and project scheduling tools. This ensures quality control data flows smoothly into existing workflows, avoiding isolated data silos.

- Pattern recognition: Over time, these systems improve their accuracy. By processing more data, they get better at distinguishing between genuine defects and normal variations in materials or techniques.

Setting Up a Computer Vision System

To fully benefit from computer vision, a proper setup is essential. Here’s what’s needed:

- Camera hardware: Depending on the project, you’ll need fixed or mobile cameras. You can choose between pre-trained AI models for quick deployment or custom models tailored to specific project needs. Pre-trained models are faster to implement, but custom models offer greater precision for unique applications.

- Cloud infrastructure: Construction sites generate enormous amounts of data – often hundreds of gigabytes daily. Robust cloud storage and processing systems are crucial for analyzing this data, storing results, and making them accessible to stakeholders across various locations.

- Workflow integration: To make the most of the insights these systems provide, they should be integrated into existing project management processes. This includes setting up automated alerts, configuring report generation, and ensuring data is shared with relevant stakeholders.

- Reliable network connectivity: A dependable internet connection is critical for uploading data, receiving software updates, and enabling real-time alerts. Since construction sites often face connectivity challenges, it’s important to plan for adequate bandwidth and backup communication options.

Setting up these systems typically requires a collaborative effort between construction teams and technology specialists. This ensures the tools are configured to meet the specific needs of each project and adapt to the unique conditions of the site.

Human Inspectors: Experience and Decision-Making

While computer vision boosts efficiency, human inspectors remain critical for making complex decisions and analyzing context. Their expertise ensures safety and quality standards are upheld.

What Human Inspectors Do Best

Computer vision may excel at routine defect detection, but human inspectors bring a level of nuanced judgment and contextual understanding that machines simply can’t replicate. They can differentiate between genuine defects and acceptable variations, particularly when faced with structural anomalies or unusual material behavior. This ability to assess site-specific conditions makes them invaluable for ensuring quality.

Human inspectors also adapt quickly to unique challenges on construction sites. Their strong communication skills allow them to provide real-time feedback and collaborate effectively with contractors, project managers, and subcontractors. This ensures that everyone involved understands quality requirements and any corrective actions needed.

Another key strength is their ability to recognize patterns. Experienced inspectors can often detect early warning signs – like slight material stress or unusual settling – before these issues develop into significant problems. This kind of insight is especially important when AI systems encounter uncertainty or ambiguity.

Where Human Inspectors Fall Short

Despite their strengths, human inspectors are not without limitations. Fatigue and distractions can lead to inconsistent performance, especially on demanding projects [2]. Subjectivity is another factor; inspectors with different training or experience may interpret the same issue differently, which can create inconsistencies, particularly in large-scale projects.

Scalability is a major challenge as well. Adding more inspectors to larger or more complex projects doesn’t always improve quality control proportionately. In fact, it can sometimes introduce more variability. Manual inspections are also time-consuming and labor-intensive, increasing the risk of overlooking subtle yet critical quality issues during busy periods. Poor documentation practices can further drive up costs [3].

These challenges highlight the importance of combining AI-driven tools with human expertise to achieve a balanced and effective approach.

Meeting U.S. Industry Standards

Human inspectors play a crucial role in ensuring compliance with U.S. industry standards, conducting safety audits, and verifying adherence to OSHA regulations and local codes [1].

A key part of their job is verifying safety programs. They ensure proper use of personal protective equipment (PPE), confirm that training requirements are met, and check that emergency response plans are in place and accessible to all workers [1][3].

Inspectors also ensure code compliance by reviewing construction methods against approved plans, confirming that materials meet required standards, and monitoring progress to ensure alignment with permitted designs. Their extensive knowledge of regulations – including electrical, plumbing, and environmental protection standards – allows them to spot compliance issues that automated systems might miss.

sbb-itb-51b9a02

Computer Vision vs Human Inspectors: Side-by-Side Comparison

When you compare computer vision to human inspectors, it’s clear each has its strengths. Computer vision stands out for speed and precision, while human inspectors bring nuanced judgment to the table.

Comparison Table: Computer Vision vs Human Inspectors

| Factor | Computer Vision | Human Inspectors |

|---|---|---|

| Detection Accuracy | 98–99.5% for specific defects | 70–85% (traditional methods may miss 20–30% of defects[5]) |

| Inspection Speed | 300 units per minute (pharmaceutical example) | Around 100 units per minute |

This comparison highlights where each approach shines.

When to Use Computer Vision vs Human Inspectors

Computer vision is ideal for tasks that demand consistent precision. For example, in the automotive sector, it increased defect detection accuracy by 30% and cut inspection times in half [4]. In electronics manufacturing, it pushed accuracy from 85% to 98%, reduced inspection times by 60%, and lowered production costs by 20% [4].

For construction startups, computer vision is particularly effective for inspecting standardized components like prefabricated panels or checking concrete surfaces for cracks. BMW saw its defect rates drop by 30% within a year after adopting AI-driven inspection systems [4].

On the other hand, human inspectors remain critical for handling complex decisions and assessing unique, site-specific conditions.

Using Both Methods Together

The best results often come from combining both approaches. Computer vision can handle rapid, continuous screening, while human inspectors focus on detailed analysis and final assessments. Together, they offer a balance of efficiency and expert judgment, ensuring high-quality outcomes.

Implementation Guide for Construction Startups

For construction startups, planning quality control measures requires careful thought. With tight budgets, U.S. regulatory requirements, and the pressure to deliver strong returns, every decision counts.

How to Choose the Right Quality Control Method

The right approach depends on the scale of your project and the resources at hand. For smaller projects or operations with fewer inspections, enhancing human inspections can be both practical and budget-friendly. This might involve advanced training, standardized checklists, or mobile tools to streamline processes.

For larger-scale operations with repetitive tasks and standardized components, adopting a computer vision system could bring long-term advantages. These systems can improve consistency and efficiency, making them a smart choice for high-volume projects.

It’s worth noting that U.S. regulations require certified human inspectors to validate critical safety inspections, even if computer vision systems flag potential issues. The pace of integrating AI tools will also depend on your team’s technical expertise. Some companies may adopt AI gradually, blending it with human oversight to ensure a smooth transition.

Finally, weigh the required investment against the potential benefits before moving forward.

Costs and Returns of AI-Powered Systems

AI-powered computer vision systems come with higher upfront costs compared to traditional methods. Expenses include hardware, software licenses, training, and ongoing maintenance. However, these systems can lead to faster project timelines and fewer quality-related setbacks, which may significantly improve your return on investment.

When evaluating such systems, consider the total cost of ownership – not just the initial investment but also recurring fees for maintenance and support. Compare these costs against the productivity gains and quality improvements expected from streamlining standardized tasks. The financial balance will depend on your project size and how extensively the system is used.

How AlterSquare Helps Construction Startups

Once you’ve identified the right method and analyzed costs, the next step is finding a tailored solution. AlterSquare offers a 90-day MVP program designed to develop custom AI tools that fit seamlessly into your workflows while staying within your budget.

Using modern tech stacks like Vue.js, Node.js, and GoLang, AlterSquare delivers scalable solutions built for long-term use. They also provide tech team augmentation, ensuring startups have the support they need to implement and maintain these systems effectively.

Additionally, AlterSquare’s expertise in generative AI and chatbot technology can add significant value. Features like automated reporting and real-time client communication allow construction startups to provide instant updates on quality control results and overall project progress. This not only improves transparency but also builds stronger trust with clients – a key advantage in a competitive industry.

Conclusion: Building Better with Smart Quality Control

The future of construction quality control isn’t about choosing between technology and human expertise – it’s about combining them to create a balanced approach that brings out the best of both worlds. By merging the speed, precision, and consistency of computer vision with the contextual understanding and problem-solving abilities of human inspectors, construction teams can achieve a level of quality control that’s both efficient and scalable across all project phases.

Computer vision systems are particularly effective at identifying routine defects and conducting initial analyses. This allows human inspectors to focus on more complex decisions and nuanced challenges, ensuring that quality standards are met without compromising efficiency. For startups, this means maintaining high-quality outcomes while scaling operations without overstretching resources.

AI-driven quality control plays a critical role in improving productivity, safety, and cost management by automating repetitive tasks. At the same time, human judgment remains crucial for verifying AI findings and providing the nuanced insights that machines cannot replicate.

This partnership between humans and AI enables construction teams to prioritize critical thinking and specialized skills, fostering better project outcomes and encouraging innovation. Instead of replacing skilled workers, this approach shifts their focus to strategic decisions that directly contribute to a project’s success.

FAQs

How can startups effectively combine computer vision and human inspectors for construction quality control?

Startups can strike a practical balance by leveraging computer vision for tasks like large-scale defect detection, progress tracking, and routine inspections. These AI-driven tools are particularly effective for handling repetitive or data-heavy tasks, offering improved efficiency, precision, and the ability to scale operations.

That said, human inspectors remain indispensable for areas that demand complex judgment, nuanced evaluations, and a deeper understanding of context – like assessing ambiguous defects or tackling unique project challenges. By integrating the strengths of both approaches, startups can refine their quality control processes, achieving accuracy while staying adaptable for more intricate situations.

What challenges arise when implementing computer vision on construction sites, and how can they be resolved?

Setting up a computer vision system on construction sites isn’t without its obstacles. Unpredictable site conditions – like inconsistent lighting, uneven ground, and shifting weather patterns – can all impact the system’s accuracy. On top of that, collecting high-quality data, integrating the technology into existing workflows, and tackling the high upfront costs can pose significant challenges.

To address these issues, companies can implement smart algorithms that adapt to changing environmental conditions, prioritize robust data collection methods, and ensure thorough testing before deployment. These measures can improve accuracy, minimize downtime, and make the system more effective in the demanding environment of a construction site.

How does combining computer vision with human inspectors help ensure compliance with U.S. construction standards and regulations?

Integrating computer vision with human inspectors brings a new level of efficiency to safety compliance. These systems can automate critical tasks such as detecting hazards in real time, monitoring for PPE violations, and flagging unapproved equipment. By operating around the clock, they minimize human error, enhance precision, and help ensure alignment with OSHA safety standards and U.S. construction regulations.

On top of that, AI-powered tools streamline the often tedious process of documentation. They can generate compliance-ready reports and keep track of regulatory requirements, taking a significant load off construction teams. This combination of technology and human oversight enables teams to uphold higher standards of safety and quality while meeting legal and industry expectations with greater ease.

Related Blog Posts

- AI-Powered Estimation: How Machine Learning is Transforming Construction Bidding

- AI-Powered Quality Control: How Computer Vision is Revolutionizing Construction Inspections

- Automated Progress Tracking: How AI Cameras Are Replacing Manual Site Surveys

- AI Safety Compliance: How Smart Cameras Prevent 80% of Construction Accidents

Leave a Reply