Augmented Reality Hard Hats: The $2B Construction Safety Revolution

Huzefa Motiwala September 27, 2025

The U.S. construction industry is embracing a $2 billion safety transformation with augmented reality (AR) hard hats. These devices combine traditional head protection with AR technology, providing workers with real-time data, safety alerts, and hazard notifications directly in their field of view. AR hard hats are designed to improve safety, productivity, and training on job sites, addressing challenges like worker shortages and complex safety regulations.

Key Takeaways:

- What They Do: AR hard hats project digital information (e.g., blueprints, safety alerts) while allowing workers to stay aware of their surroundings.

- Features: Sensors for hazard detection, cameras, wireless connectivity, and compliance with OSHA and ANSI standards.

- Benefits: Reduced accidents, faster training, and enhanced communication between workers and supervisors.

- Challenges: High costs, worker resistance to new tech, and connectivity issues on remote sites.

- Future Trends: AI-powered safety tools, immersive training, and improved offline functionality.

AR hard hats are reshaping construction safety by integrating digital insights with physical protection, making them a valuable tool for modern job sites.

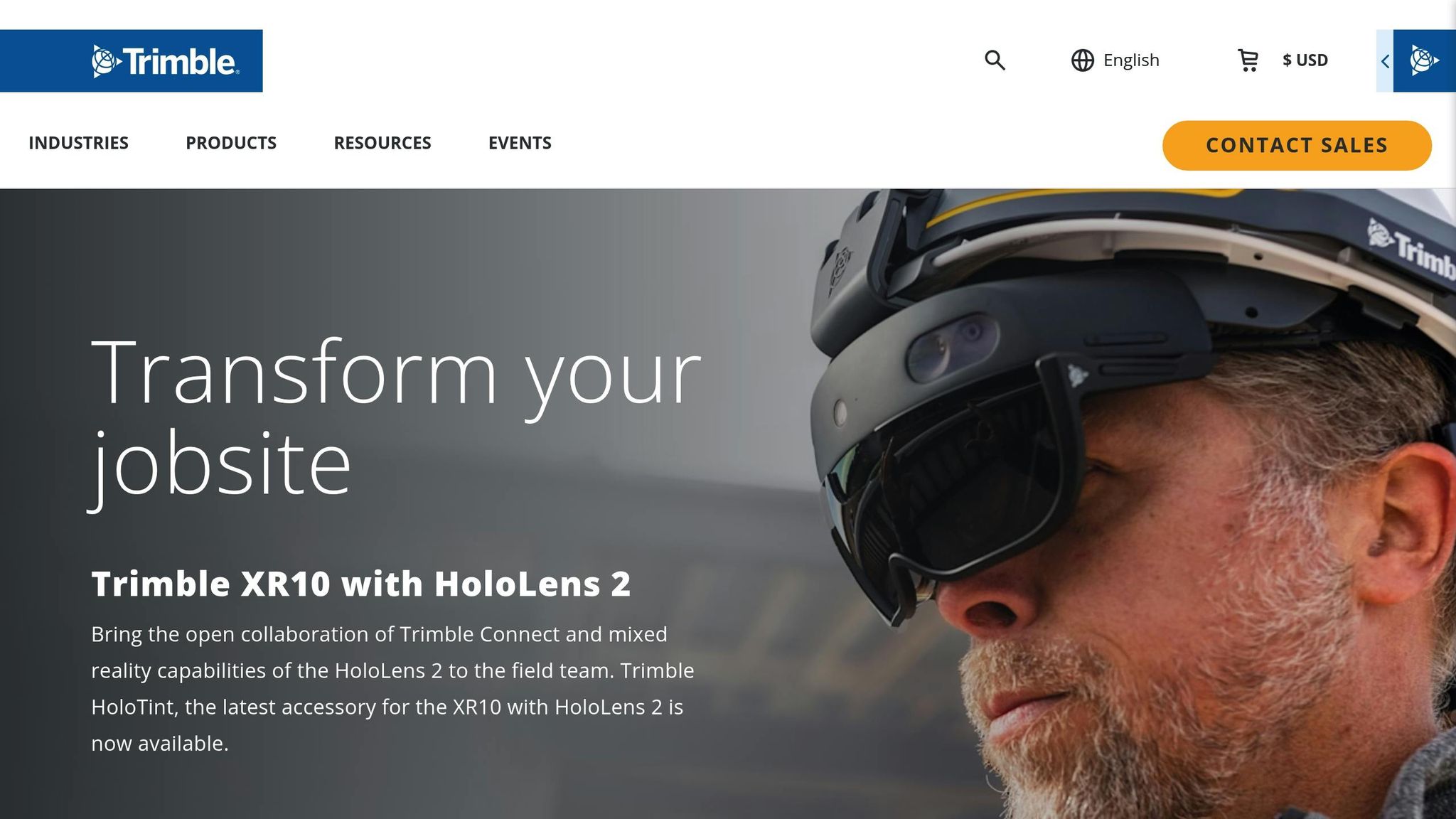

Trimble XR10 mixed reality hard hat in pilot use

Core Features and Technologies in AR Hard Hats

AR hard hats combine cutting-edge digital tools with traditional safety gear, designed to withstand tough construction conditions while improving both safety and efficiency. These advancements come to life through specific features and technologies embedded in the hard hats.

Key Components of AR Hard Hats

To prioritize worker safety, AR hard hats are equipped with transparent display systems that project digital information directly into the user’s line of sight. Cameras – mounted both forward-facing and inward – play a key role by capturing environmental data. This enables advanced functions like real-time hazard detection and personalized display adjustments. Built-in sensors, such as gas, temperature, and motion detectors, further enhance safety by identifying dangerous substances, monitoring environmental conditions, and triggering alerts for incidents like falls or sudden impacts.

Reliable communication systems are another critical feature. These hard hats are equipped with Wi-Fi, cellular, and Bluetooth connectivity, along with integrated audio systems, including bone conduction technology. Together, these tools enable hands-free communication, real-time data sharing, and seamless integration with cloud-based platforms.

How AR Improves Safety and Productivity

AR technology provides workers with real-time, actionable data. For instance, it can alert users to the status of nearby equipment or outline safe zones around heavy machinery. By offering these proactive warnings, AR hard hats help reduce the risk of accidents caused by moving equipment or unstable structures.

Communication is another standout advantage. Workers can share live video feeds with supervisors or remote experts, speeding up troubleshooting and decision-making processes. Additionally, AR-powered training tools offer step-by-step instructions for complex tasks and safety procedures, simplifying training sessions and ensuring compliance with safety protocols. These features are designed to align with strict safety and regulatory requirements, further supporting productivity on job sites.

Regulatory Compliance for AR Hard Hats

AR hard hats are built to meet the same stringent safety standards as traditional helmets while integrating advanced electronics. They adhere to OSHA regulations, such as those outlined in 29 CFR 1926.95, which mandate protection against electrical hazards and physical impacts. Additionally, these hard hats comply with ANSI/ISEA Z89.1 standards, ensuring that their electronic components don’t compromise the helmet’s protective capabilities.

In high-risk environments where explosive materials may be present, AR hard hats must meet intrinsic safety certifications, guided by standards like NFPA 70, to ensure their electronics don’t ignite flammable substances. Furthermore, these systems incorporate data privacy measures alongside OSHA, ANSI/ISEA, and FCC compliance to protect both workers and operational integrity. Meeting these regulatory benchmarks is essential for gaining traction in the U.S. construction industry, solidifying AR’s role in advancing site safety.

Applications of AR Hard Hats in US Construction

AR hard hats are reshaping the construction industry, addressing both safety concerns and training needs. These advanced tools act as real-time safety aids and training enhancers, playing a key role in the $2 billion safety transformation currently underway in US construction. Their impact spans two major areas: hazard detection and skill development.

Real-Time Hazard Detection

AR hard hats go far beyond the basic function of head protection. They come equipped with sensors and environmental monitoring systems that actively identify hazards on-site. This real-time detection helps workers stay alert to potential dangers, creating safer work environments and reducing the likelihood of accidents.

Worker Training and Skill Development

Training is being revolutionized with AR hard hats, which offer immersive, on-site simulations. These simulations make complex information easier to understand and remember while minimizing costly errors. By catering to different learning styles – whether visual, hands-on, or auditory – these tools ensure that workers grasp critical skills more effectively.

This technology not only speeds up the onboarding process for new employees but also helps seasoned workers refine their expertise. Additionally, these advancements contribute to better compliance with safety standards and improve overall operational oversight, making them a valuable asset on any construction site.

Leading AR Hard Hat Technologies and Companies

The AR hard hat market is advancing quickly, blending augmented reality with durable head protection to improve safety and efficiency. These advancements highlight the innovative features and practical benefits AR hard hats bring to the table.

Top AR Hard Hat Products

Modern AR hard hats combine traditional head protection with augmented reality to boost safety and productivity on construction sites. These devices typically display critical information – like blueprints, hazard warnings, and step-by-step instructions – right in the worker’s line of sight. At the same time, they meet the rigorous protective standards required for U.S. construction environments.

Features and Benefits

AR hard hats go beyond basic protection, offering a range of advanced capabilities:

- Real-time data projection paired with voice-activated, hands-free controls helps workers stay informed without interrupting their tasks.

- Built tough, these devices can handle harsh conditions, including exposure to dust, moisture, and extreme temperatures.

- Many models integrate seamlessly with construction management software, allowing project data and operational records to stay synchronized.

By transforming a standard hard hat into a multifunctional tool, these innovations enhance worker safety and streamline day-to-day operations.

Business Impact

The financial advantages of using AR-enhanced hard hats stretch far beyond the upfront investment. Enhanced safety can significantly lower costs associated with workplace injuries. For instance, traumatic brain injuries account for 17% of workers’ compensation claims costing between $3 million and $5 million, and 30% of claims exceeding $10 million [1]. Additionally, having instant access to critical data reduces downtime, boosts productivity, and simplifies employee training, making these hard hats a smart choice for forward-thinking companies.

sbb-itb-51b9a02

Challenges and Future Outlook for AR Hard Hats in the US

AR hard hats bring a lot of potential to the construction industry, but they also come with hurdles that need to be addressed. Tackling these challenges is critical for making the most of this technology on American construction sites. By navigating these obstacles and exploring emerging opportunities, the construction sector can better position itself to improve safety and efficiency through AR hard hats.

Adoption Barriers

The high upfront cost of AR hard hats, combined with expenses for training, licensing, and maintenance, can make companies hesitate to invest.

There’s also skepticism among workers, particularly those with years of hands-on experience. Many are cautious about high-tech solutions, seeing them as complicated or even as a threat to job security. The learning curve for AR interfaces can amplify these concerns. To ease this resistance, companies need to prioritize clear training programs and effective change management strategies.

Practical issues like battery life and network connectivity also pose challenges. Construction sites, especially remote or rugged ones, often lack reliable internet access. Ensuring that AR hard hats can function effectively in these environments – without constant connectivity – is crucial for their success.

Integration with US Construction Workflows

For AR hard hats to truly deliver value, they need to fit seamlessly into existing construction workflows. The good news? They can sync with widely used tools like Autodesk Construction Cloud, BIM 360, Revit, Navisworks, and Civil 3D by leveraging Building Information Modeling (BIM) and Common Data Environment (CDE) platforms. This integration allows workers to access updated blueprints, safety protocols, and project details without disrupting their usual processes.

Another key feature is remote assistance. With tools like interactive annotations and camera sharing, off-site experts can provide real-time guidance, cutting down on the need for in-person site visits and reducing downtime. On-site technical support can also smooth the transition, helping workers get comfortable with the technology. These integration efforts make AR hard hats more practical and pave the way for future advancements.

Future Trends and Developments

As the industry overcomes current challenges, AR technology is expected to evolve rapidly. By 2025, wearable AR devices could become a regular sight on construction sites, aligning with broader trends in digital transformation and proactive safety measures.

One exciting development is the rise of AI-powered AR assistants. These tools could provide intelligent, real-time guidance, helping workers spot hazards early and offering safety recommendations on the fly. Another area of growth is immersive training. By combining AR and VR, companies can create hands-on training programs that prepare workers more effectively. Studies show that using AR for safety training can reduce first-year workplace accidents by 18% compared to traditional methods[2].

The benefits don’t stop there. Companies using AR have reported a 30% boost in project collaboration and communication, and rework – a common issue that can account for up to 10% of total construction costs – could be reduced by as much as 25%[3].

Future versions of AR hard hats are likely to address connectivity issues by storing more project data locally. This improvement would ensure that workers have access to critical information, even in areas with poor or no internet access. As prices come down and the technology becomes more advanced, AR hard hats could become as standard as hard-toe boots or safety goggles, reshaping construction practices across the U.S.

How AlterSquare Accelerates AR-Driven Construction Innovation

As augmented reality (AR) hard hat technology shifts from experimental to everyday use, construction companies need dependable tech partners to guide this transition. AlterSquare stands out by helping firms create scalable safety solutions that deliver measurable results on U.S. job sites. Here’s how their unique approach drives AR advancements in the construction industry.

Custom AR Solutions for U.S. Construction

AlterSquare tailors its AR hard hat solutions to address the specific challenges faced on American construction sites. Their 90-day MVP (Minimum Viable Product) program is designed to quickly prototype and test AR safety features, incorporating worker feedback to ensure practical, on-the-ground usability. In an industry where safety improvements are urgent, this rapid timeline is a game-changer.

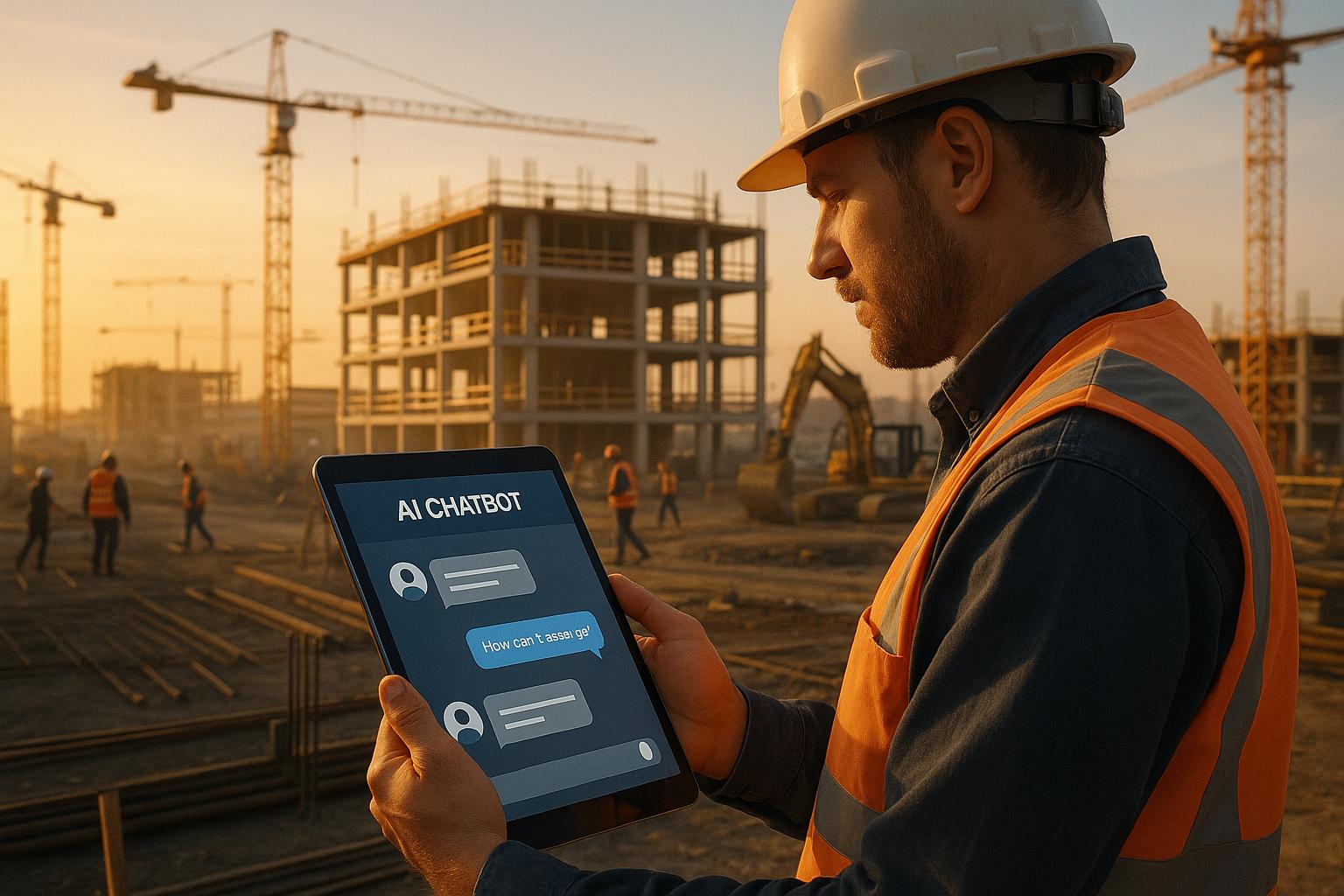

The company’s use of generative AI and chatbot technologies brings intelligent safety assistants to life. These tools provide real-time guidance to workers, generate safety reports based on visual data, and create personalized training modules tailored to individual performance.

To ensure seamless integration, AlterSquare employs a robust tech stack – featuring Vue.js, Nuxt.js, GoLang, and Node.js – that connects AR hard hat data directly to existing construction management and compliance systems. This ensures that new AR solutions can work within current workflows without disruption.

Their rapid prototyping approach allows companies to test AR features before committing to full-scale deployment. For instance, a firm might trial hazard detection algorithms for electrical work, validate their effectiveness with on-site teams, and then expand the technology to other trades once proven effective.

Delivering Measurable Safety and Efficiency Gains

AlterSquare’s structured approach helps construction companies overcome common challenges that can derail AR adoption. Their I.D.E.A.L. framework – covering discovery, design, agile development, launch, and support – keeps AR projects focused on real safety needs rather than getting bogged down in technical hurdles.

Integrating AR hard hats with older systems is another area where AlterSquare excels. Many construction firms rely on legacy project management tools and safety databases that weren’t built to handle real-time AR data. AlterSquare modernizes these systems without interrupting daily operations, allowing companies to benefit from AR technology without a complete digital overhaul.

A key strength of AlterSquare is their tech team augmentation model. By embedding engineers who understand both AR technology and safety requirements within construction teams, they ensure that solutions remain practical and user-friendly throughout development.

Their portfolio includes success stories of rescuing struggling projects and delivering critical features in tight timeframes. These efforts have led to increased revenue, better profit margins, and higher client satisfaction. Feedback from clients highlights the company’s ability to offer timely support during AR implementation challenges.

Why AlterSquare is the Right Tech Partner

Adopting AR hard hats requires a partner who understands both the technology and the regulatory landscape. AlterSquare’s compliance-first approach ensures that AR safety solutions are designed to meet OSHA and industry standards from the outset, avoiding costly redesigns later.

For startups venturing into AR safety products, AlterSquare’s founder enablement programs are particularly valuable. Non-technical founders gain the insights needed to make informed decisions about AR features, while technical founders benefit from the additional resources required to scale their solutions efficiently.

AlterSquare’s commitment to continuous improvement aligns perfectly with the iterative nature of AR hard hat deployment. As workers provide feedback and safety data reveals new insights, their post-launch support ensures that AR systems adapt to the evolving needs of construction sites.

With deep expertise in AI-driven technologies, AlterSquare is well-prepared for the future of AR hard hats. As these devices advance to include predictive safety analytics, automated compliance reporting, and personalized training recommendations, AlterSquare’s capabilities ensure that construction companies remain ahead of the curve.

For firms ready to tap into the $2 billion AR hard hat market, AlterSquare offers the technical know-how, industry expertise, and proven processes needed to turn cutting-edge safety technology into a competitive advantage.

Conclusion: The Future of AR Hard Hats in Construction

AR hard hats are reshaping how safety and efficiency are approached on construction sites across the U.S. By combining durable physical protection with real-time digital insights, these devices are setting a new benchmark for worker safety. As the market for AR hard hats moves toward a projected value of $2 billion, it’s clear that these tools are becoming an essential part of modern construction practices.

AlterSquare is at the forefront of this transformation. Through their rapid MVP program and structured I.D.E.A.L. framework, they help companies seamlessly adopt AR safety solutions. This approach ensures that innovation translates directly into improved safety measures, empowering construction firms to better protect their workforce while embracing cutting-edge technology.

FAQs

How do augmented reality (AR) hard hats improve safety and efficiency on construction sites?

AR hard hats are transforming construction safety and efficiency by displaying real-time data, 3D models, and hazard alerts directly in workers’ line of sight. This instant access to information helps workers spot potential dangers more quickly, lowering the risk of accidents and cutting down on expensive rework.

These high-tech hard hats also boost productivity by simplifying communication and offering built-in training tools. Workers can pull up essential details without stepping away from their tasks, improving precision and keeping projects on track. By bringing advanced technology to the job site, AR hard hats are reshaping how construction teams operate, all while keeping safety front and center.

What challenges do companies face when adopting AR hard hats, and how can they address them?

Adopting AR hard hats isn’t without its difficulties. Companies often face high initial costs, hardware challenges like outdated devices or limited processing capabilities, and usability issues, including discomfort or potential distractions for workers. These obstacles can slow down adoption and limit the technology’s impact.

To overcome these challenges, businesses should focus on implementing scalable, easy-to-use AR solutions that work well with their current systems. Comprehensive training programs can help workers feel confident using the technology, while investing in hardware that’s both efficient and comfortable can enhance usability. By addressing these key areas, companies can unlock the full potential of AR hard hats to boost safety and productivity.

How do augmented reality (AR) hard hats meet construction safety standards in the US?

AR hard hats are designed to meet ANSI/ISEA Z89.1 standards, a key safety benchmark widely acknowledged by OSHA. This certification ensures they provide reliable protection against impacts, falling objects, and electrical hazards – essential features for high-risk construction environments.

These helmets undergo extensive testing to verify their impact resistance and electrical safety performance. By aligning with these federal safety standards, AR hard hats combine cutting-edge technology with dependable protection, making them a practical choice for construction sites.

Related Blog Posts

- Mobile-First Construction: Bringing Field Operations into the Digital Age

- Why Construction Tech UX Is Different: Designing for Jobsite Realities

- VR/AR Applications Transforming Client Presentations for Construction Projects

- AI Safety Compliance: How Smart Cameras Prevent 80% of Construction Accidents

Leave a Reply